our plastics story

Keeping our plastics in the loop - TRESemmé

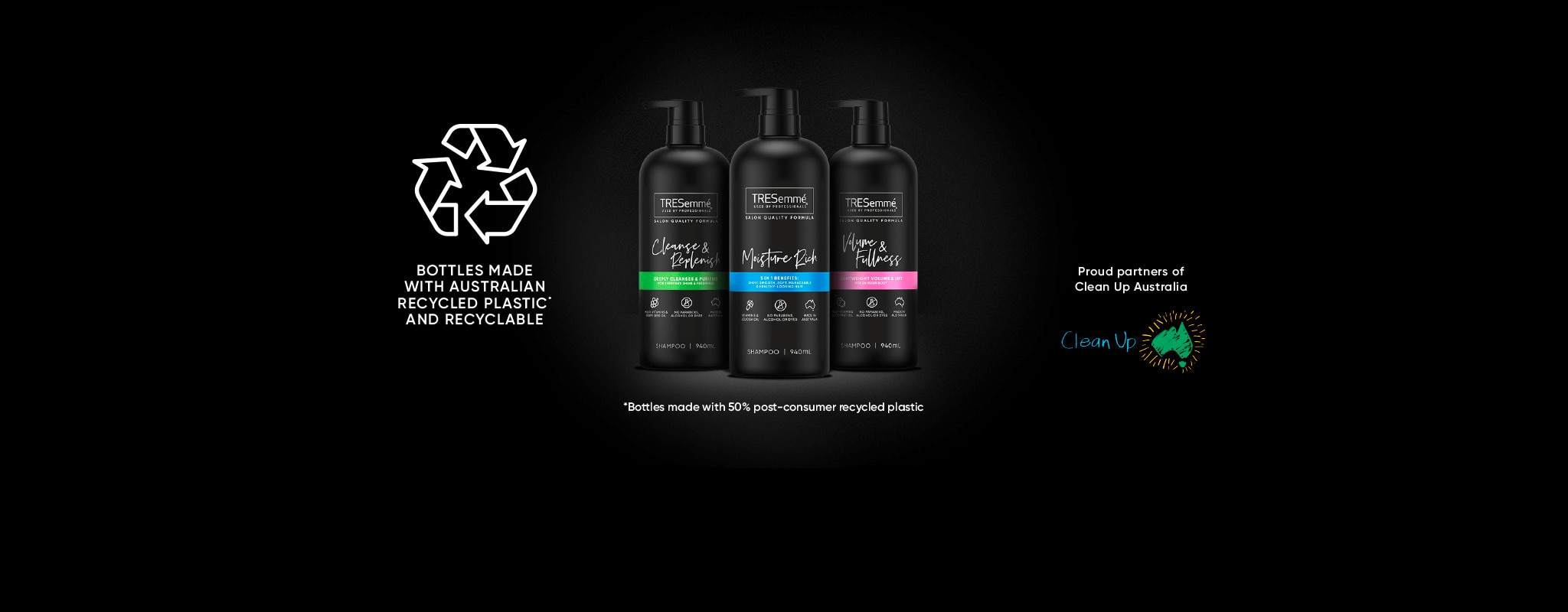

Here at TRESemmé we are striving to make a positive impact on women and our on planet. We have been working hard to reduce our packaging waste and our footprint on the planet. We can now proudly announce In Australia & New Zealand our TRESemmé shampoo and conditioner bottles are now made with 50% post-consumer Australian recycled plastic. Not only this, our R&D teams have developed pioneering innovation that allows TRESemmé bottles to be made from detectable pigment that makes black plastic recyclable, so now all our bottles can be recycled! In the past, the darker the bottle the harder to sort at a recycling unit. This means that in Australia alone we have the potential so save 5,026,053 bottles going into landfill each year!

Keeping our plastics in the loop - Unilever

The growing challenge of plastic in the environment means it is more urgent than ever to find solutions to reduce, reuse, recycle and recover ‘post-consumer’ plastic waste!

Urgent action is needed on multiple fronts. As a consumer goods company, we’re acutely aware of the causes and consequences of the linear “take-make-dispose” model. And we want to change it.

From a purely business perspective, discarding plastic makes zero sense. Plastic packaging waste represents an $80-$120 billion loss to the global economy every year according to the World Economic Forum. A more circular approach is needed, where we not only use less packaging, but design the packaging we do use so it can be reused, recycled or composted.

In a circular economy, materials are regenerated and constantly flow around a ‘closed loop’ system, rather than being used a few times and then discarded. It means that the value of materials, including plastics, is not lost by being thrown away. A more circular use of materials means lower costs and less waste. It means new sources of value for our customers and consumers, better risk management of raw materials, and improved approaches to the supply chain.

The Waste & Packaging pillar of our Unilever Sustainable Living Plan contributes primarily to two of the UN Sustainable Development Goals (SDGs): Responsible Consumption & Production (SDG 12) and Life Below Water (SDG 14). And moving away from this linear model of consumption is key.

We want to use far more PCR plastic in the future and recapture our own packaging. The biggest challenge is the limited availability of high-quality recycled waste materials (owing to a high demand on the market), particularly in developing and emerging markets. To address this, we have been working with others to tackle wider infrastructural issues such as local collection and sorting facilities and to build the technical and commercial viability of reprocessing them at scale. As a result, we have opened many new PCR sources during 2018.

We expect our use of PCR materials to accelerate rapidly over the next few years as the design processes begin to deliver at scale. This will help us achieve our global commitment to include at least 25% recycled content in our plastic packaging by 2025.